Inventory Management.

Smarter. Faster.

Our RFID inventory software, paired with intelligent hardware, puts real-time data at your fingertips—so you can stop reacting to inventory problems and start managing them proactively, with greater speed, insight, and scale.

Inventory Management.

Smarter. Faster.

Our RFID inventory software, paired with intelligent hardware, puts real-time data at your fingertips—so you can stop reacting to inventory problems and start managing them proactively, with greater speed, insight, and scale.

Companies leveraging RFID tracking experienced:

1

Reduced manual processes

2

Increased Productivity

3

Reduced human errors

4

Improved customer satisfaction

5

Lowered costs

Stay Productive. Less Manual Labour.

Opening every cardboard box to count new instocks

Manually counting and repacking of stocks back to shelves

Spending whole day to do stock take

Struggling to track low stock in real-time

Spending hours doing inbound and outbound of stocks

Inventory Management Simplified to Six Easy Steps

1.PO registration

T-CUBE Core provides the capability to generate an RFID tag number and print the tags, right at your production plant.

2.Instock

Bulk scan & inbound arrived goods using RFID mobile scanner or gantry with precision. Automate data capture, and eliminate manual errors.

3.Relocation of stock

Easily view goods movement and relocation—whether you’re optimizing storage or transferring stock to retail outlets.

4.Stock take & cycle count

What used to take days can now be done in hours—with RFID-enabled, real-time counts that boost accuracy and reduce downtime.

5.Order fulfillment & packing

Generate your picking lists from your orders, and your workers can get down to packing right away.

6.Outbound of stocks

Track your orders from the time they are placed, to the time they are out for delivery.

Each SKU’s movement is logged — from receiving to in-store placement. This eliminates blind spots, ensures replenishment triggers are based on live data, and helps avoid stockouts and overstocks.

Visibility of Stock Movements to Avoid Stockouts & Overstocks

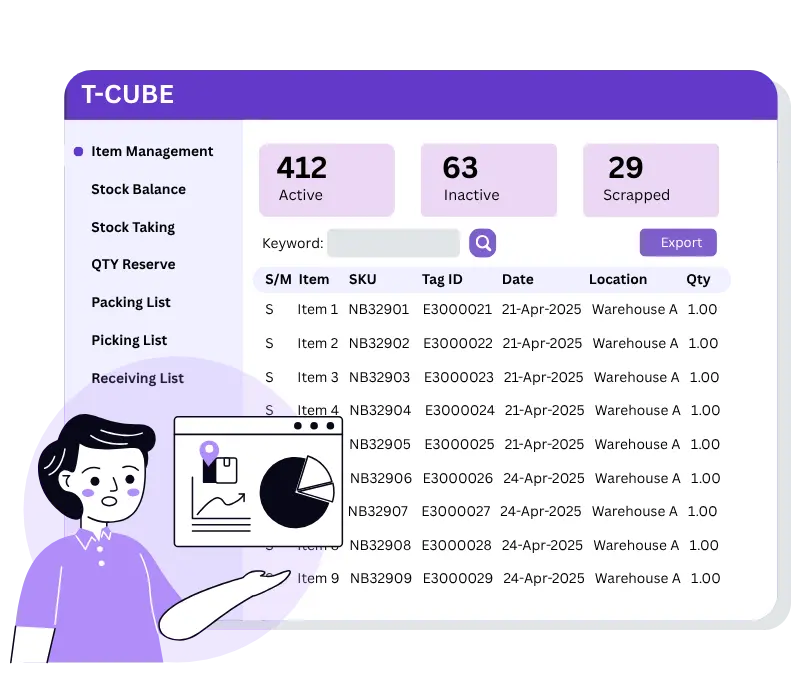

Real-time Inventory Data At Your Fingertips

Powerful view of real-time inventory master data— providing instant access to stock levels across all warehouse or retail locations, and movement history in one centralized interface, so your team can make informed, agile decisions without the clutter of traditional systems to ensure stock accuracy.

T-CUBE also integrates with ERP to ensures stock accuracy by providing real-time, automated inventory updates directly into the ERP system.

Alarm systems to prevent theft using RFID gantry

Automate multiple check-out of inventories using RFID antenna

Alert function for depleted stocks

Stock management (location specific)

Stocktaking/ Cycle Counting

Smarter Retail Starts with RFID Inventory Management System

Gain real-time visibility, reduce losses, and enhance security across your store. Our RFID solution empowers retail businesses to track inventory with accuracy using gantry system—minimizing out-of-stocks, preventing theft, and streamlining replenishment. From stockroom to storefront, you’ll have full control over your inventory and peace of mind knowing every item is accounted for.

Outbound of stocks for cash & carry items

How RFID Transforms

Supply Chains Processes

Transform supply chain operations by enabling real-time visibility, automation, and accuracy across every stage—from production to delivery. By tagging items, pallets, or containers with RFID labels, businesses can track the movement of goods automatically, without manual scanning or line-of-sight requirements.

Real-Time Tracking: Monitor inventory and shipments across warehouses and distribution points

Sustainability Benefits: Increase product shelf life—reducing spoilage of unused goods

Faster Processes: Automate receiving, picking, and shipping workflows

Supply Chain End-To-End Tracking

RFID provides end-to-end tracking of goods from manufacturing to distribution to retail. Every movement is automatically recorded, giving stakeholders real-time visibility into the location and status of inventory across the entire supply chain.

Order Planning & Stock Movements

As items move in or out of storage, RFID readers automatically log their movement—eliminating the need for manual scanning. This real-time tracking ensures that every item is accounted for during picking, packing, shipping, or internal transfers.

Warehouse Space Optimization

With continuous data from RFID, the warehouse module can analyze space utilization patterns and suggest optimal placement based on size, weight, frequency of access, and item category—minimizing wasted space and maximizing storage density.